Bottom price Plasma Cutting Stainless Steel – High quality plasma and flame cutting part – Hengli

Bottom price Plasma Cutting Stainless Steel – High quality plasma and flame cutting part – Hengli Detail:

Hengli’s manufacturing uses CNC plasma machines. Plasma cutting technology enables us to cut metal with a thickness of 1…350 mm. Our plasma cutting service is in accordance with quality classification EN 9013.

Plasma cutting, like flame cutting, is suitable for cutting thick materials. Its advantage over the latter is the possibility to cut other metals and alloys that are not possible with flame cutting. Also, the speed is significantly faster than with flame cutting and there is no necessity for pre-heating the metal.

Profiling Workshop was founded in 2002, which is the earliest workshop in our company. About 140 workers. 10 sets flame cutting machines, 2 sets of CNC plasma cutting machines, 10 hydraulic pressers.

Specification of CNC Flame Cutting Service

No. of equipment: 10 pcs(4/8 guns)

Cutting thickness: 6-400mm

Working Table:5.4 * 14 m

Tolerance: ISO9013-Ⅱ

Specification of CNC Plasma Cutting, Leveling & Forming Service

CNC Plasma Cutting Machine

No. of Equipment: 2 sets(2/3 guns)

Table Size: 5.4*20m

Tolerance: ISO9013-Ⅱ

Cutting metal: carbon steel, stainless steel, copper, aluminum and other metals

Hydraulic Presser

No. of Equipment: 10 sets

Stress: 60-500T

Applied for : leveling & forming

Advantages of Plasma Cutting

Lower cost – One of the big benefits is the lower cost of a plasma cutting service compared to other cutting methods. The lower price for the service derives from different aspects – operational costs and speed.

High speed – Plasma cutting service’s one of the main benefits is its quickness. This is especially evident with metal plates, while laser cutting is competitive when it comes to sheet cutting. The increased speed enables to produce larger quantities in a given time-frame, lessening the cost per part.

Low operational requirements – Another important factor to keep service prices down. Plasma cutters use compressed air and electricity to operate. This means that there is no expensive equipment needed to accompany a plasma cutter.

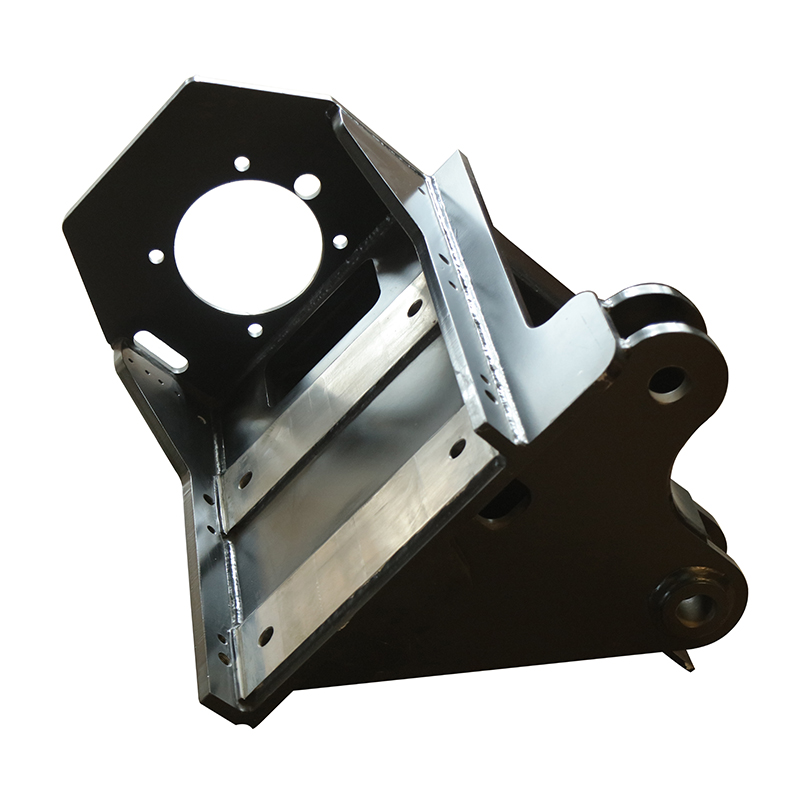

Product detail pictures:

Related Product Guide:

The customer satisfaction is our primary target. We uphold a consistent level of professionalism, quality, credibility and service for Bottom price Plasma Cutting Stainless Steel – High quality plasma and flame cutting part – Hengli , The product will supply to all over the world, such as: Turkey, Azerbaijan, Nicaragua, For more than ten years experience in this filed, our company has gained high reputation from home and abroad. So we welcome friends from all over the world to come and contact us, not only for business, but also for friendship.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.